Safety at Work

We have all practical safety measures that are essential in the foundry industry.

Read More

We have all practical safety measures that are essential in the foundry industry.

Crafting excellence with high-technology factory that is also environmental friendly.

Our cutting edge production technology provide 100% quality passed product.

We believe business is not only an exchange of products and revenue, it is a journey where we are with each other for meaningful change in the world. To make it happen, we as a family are always ready in all circumferences with the philosophy of Efforts till Excellence.

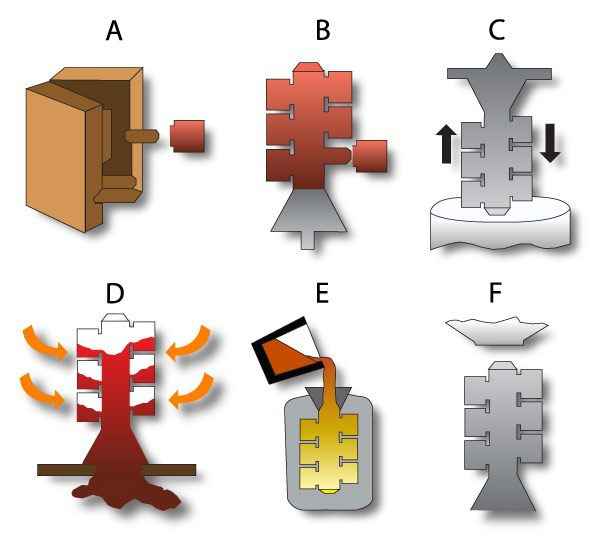

CAPTAIN TECHNOCAST, established in 2010 and listed on BSE in 2017, is the pioneer and largest manufacturer in the production of investment casting (lost-wax process) with a state-of-the-art facility with the production capacity of 2400 MT/annum located strategically at Rajkot in the western province of India. The company has built up a good reputation and recognition among domestic as well as international customers. We satisfy the high standards of quality in the sector concerning product quality, delivery reliability, process stability, and total cost of ownership.

Step into the realm of limitless possibilities of metal engineering, where precision meets versatility. Our solutions are not confined by industry boundaries; they’re crafted to elevate performance across diverse sectors.

Captain Technocast conglomerate setting new standards across industries with a unified vision driving every endeavor. We redefine excellence in every sector.

Offered products are manufactured using the best-grade raw material and advanced technology at our hi-tech manufacturing facility in compliance with the set industry norms. The entire range is widely appreciated among our esteemed clients due to its low maintenance, corrosion resistance, sturdiness, high durability, optimum finish, and reliability. Clients can avail themselves of these products from us at market-leading prices.

By leveraging their extensive industry networks and market insights, these firms help clients forge strategic alliances, joint ventures, and strategic.